ENERGY RECOVERY

Air-to-air recovery, waste heat recovery, compressor heat recovery, HVAC system optimisation, LEV systems optimisation, recirculation and de-stratification systems

Less of a Drain...

Energy recovery from manufacturing processes is becoming more critical due to the ever rising cost of utilities. The Climate Change Levy encourages the industrial sector to improve energy efficiency and reduce emissions of greenhouse gases.

Industrial processes use large quantities of fuel and electricity that ultimately produce heat , much of which results in energy waste or heat loss. The amount of energy required to reheat the displaced air can be considerable, making eat recovery a viable option.

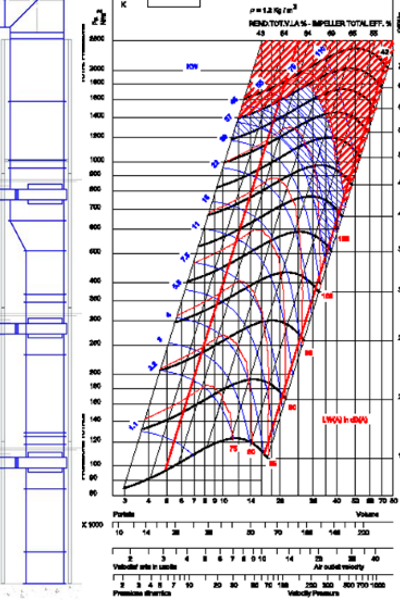

MECHON has developed energy saving systems that are able to ensure energy recovery of up to 80%, utilising plate heat exchangers, thermal (heat) wheels, recuperators, regenerators, filtered air recirculation and heat pumps.

Designs could be incorporated into new or existing installations, with the added incentive of recovering the part of the capital costs under the Enhanced Capital Allowance Scheme

Case Studies

Thermal Wheel

Recovery of heat using thermal wheels on styrene LEV systems

Compressed Air Energy

Energy recovery from bottle blowing plant at Coca Cola

Send Us an Email

How We Work.....

With our in-house team of technical experts, we are able to delivery complex high-technology solutions, within strict cost and time constraints. We are able to consider all aspects of the project to ensure that the operation of processes or supporting services are not affected by the introduction of new systems.

Design

We work with our clients to develop the initial strategic brief. This brief is then evolved into conceptual and final design specification.

Project Management

Our management procedures have evolved with our experience to delivery projects on time and on budget.

Validation

We verify the design and equipment selections of contractor and validate any installations to ensure their correct and safe operation.