Case Study

Coca Cola

Energy Recovery on Bottle Blowing Plant

Sustainable Drinks

Three ventilation systems designed by Mechon supply external air to the plastic bottling blowing areas at Coca Cola Enterprises in Edmonton. The Client established that the area required additional heating during the winter months and further commissioned MECHON to design integrated heat recovery systems.

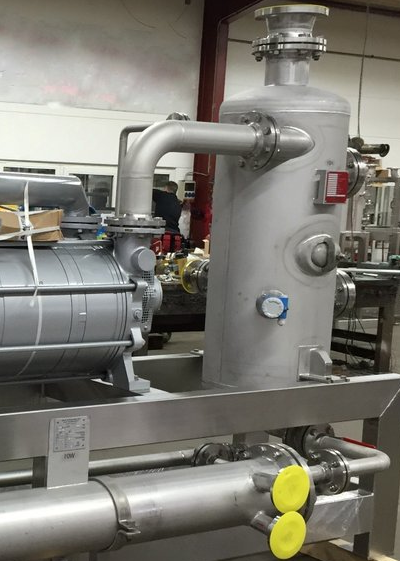

The plastic bottle blowing process uses several specialist high pressure compressors which are temperature-controlled via water-cooled circuits. It was determined that energy from the water circuits should be recovered using water-to-air heat exchangers, with each supply system having its own exchanger.

The energy from the compressors water jacket cooling systems is transferred to the incoming air, heating it before it enters the facility.

Similar Case Studies

Thermal Wheel

Recovery of heat using thermal wheels on styrene LEV systems

Distribution Centre

Evaporative cooling systems for Amazon.co.uk fulfilment centres

Formula 1

Dust Control System for Alumnium SLM Facility

Send Us an Email

How We Work.....

With our in-house team of technical experts, we are able to delivery complex high-technology solutions, within strict cost and time constraints. We are able to consider all aspects of the project to ensure that the operation of processes or supporting services are not affected by the introduction of new systems.

Design

We work with our clients to develop the initial strategic brief. This brief is then evolved into conceptual and final design specification.

Project Management

Our management procedures have evolved with our experience to delivery projects on time and on budget.

Validation

We verify the design and equipment selections of contractor and validate any installations to ensure their correct and safe operation.